Where to Work in Buffalo: In a Pottery

Written for the Express by L. E. Moss

Buffalo Illustrated Express, February 19, 1910

Of course, there are many big industries in Buffalo that everybody knows all about - or at least something about. But it is surprising how many smaller ones there are, just as important in their way, just as interesting, of whose very existence nobody knows. Everybody knows that Buffalo makes a great deal of iron and steel, flour and so forth, and that a great business is done in the enormous elevators that make hideous the water front. But who knows that right here in Buffalo several hundred people are busy making pottery-arid that the ware turned out from our own city is gaining a name for itself the country over, and even abroad? Yet that is the case.

The pottery overlooks a broad open space far out toward the outskirts of the city. A large brick building of four stories it is, with great cones protruding from the roof, whence at certain times streams of smoke are seen issuing. These are the kilns, the very heart of the pottery.

Entering the building the first impression is of a clatter of thousands upon thousands of dishes, big and little. Everywhere are men and boys and girls, wearing great white or khaki aprons or overalls or dusters, and spattered from head to foot with the creamy slip. Through and into the receiving-room, where the clay is taken from the cars, you go. It might be a flour mill, for the layer of white dust that spreads over everything. And within the bins to either side are tons of white clay, that might be a very lumpy kind of wheat flour. Near at hand lies a pile of clay of different appearance - dark, blackish brown and in tight, puttyish lumps.

Entering the building the first impression is of a clatter of thousands upon thousands of dishes, big and little. Everywhere are men and boys and girls, wearing great white or khaki aprons or overalls or dusters, and spattered from head to foot with the creamy slip. Through and into the receiving-room, where the clay is taken from the cars, you go. It might be a flour mill, for the layer of white dust that spreads over everything. And within the bins to either side are tons of white clay, that might be a very lumpy kind of wheat flour. Near at hand lies a pile of clay of different appearance - dark, blackish brown and in tight, puttyish lumps.

"That," said the superintendent, "is the ball clay used to give plasticity to the clay. We use kaolin, ball clay, silica and feldspar. The proportions? That's my secret. Nobody else in the place knows that but myself. See that scale? Well, the weigher just piles on the clay until it reaches that point – he doesn’t know the weight – and ball clay to another degree. I set the mechanism to take the exact proportion according to the formula I've worked out in the laboratory."

From the scale, the weighed clay is piled on a little elevator that lifts it and dumps it into the plunger. This is a machine filled with knives that tear and cut the lumps to pieces, and mix the ingredients together. In the plunger a certain proportion of water is mixed with the prescription, and it runs down into a tank beneath the floor. It was at this point that the superintendent lifted a small trapdoor, revealing the well of creamy clay eddying and twisting below. "That's what we call an agitator," said he. "The revolving of the mass keeps it from settling or the ingredients from separating."

And so from its well beneath the floor it is pumped up again and gradually poured out on a kind of machine that acts as a screen - a couple of sheets of fine bolting cloth, parallel and a few inches apart, that are kept constantly vibrating rapidly by machinery.

"That's what potters call the lawn," said the interesting guide, pointing to the sieve. "You would probably call it a sieve - but it's the lawn to us. That cloth has 100 to 150 meshes to the square inch. That red brown stuff you see is iron, and see those coarse grains of sand and gravel-those have been sifted out." The latter are scraped from the lawn every little while by a boy and gathered in a tank below.

"The slip all goes through. What is slip? That's another potter's term, If you asked me what it came from I couldn't tell you. It's been handed down from old English with the potter's trade."

It might be a cave hollowed from white clay with subterranean beings moving noiselessly about in the dim light - that sliproom. Below the floor again the sifted slip finds its way to a second agitator, where it is again whirled and kept on the move until it is lifted by a pump and run into the filter. It is here that the mixture of potter's clay is run into thick canvas sacks from which the water drips into a tank, and the firm mass of clay is left to be taken out when the process is ready.

It might be a cave hollowed from white clay with subterranean beings moving noiselessly about in the dim light - that sliproom. Below the floor again the sifted slip finds its way to a second agitator, where it is again whirled and kept on the move until it is lifted by a pump and run into the filter. It is here that the mixture of potter's clay is run into thick canvas sacks from which the water drips into a tank, and the firm mass of clay is left to be taken out when the process is ready.

"That water from the clay is the purest filtered water," said the guide. "We use it over again in mixing the clay."

A couple of young men came with a little truck upon which they loaded the slabs of putty-like substance from the sacks and trundled it away through a dim doorway. The guide followed, talking as he went. "The sliphouse doesn't take much work," said he. "Four men do the whole thing there. Now this is the clay cellar, and that is the pug mill. It takes two men."

There was clay everywhere in this dim cellar - piles of it, damp and solid as walls of putty. A youth, slim and silent, was working with a wire cutter slicing off great cubes of the mass and carrying it to the great mouth of the mill at the other side of the cellar. Here again the mass is tormented and torn and twisted - there is no rest for the weary clay. Its final usefulness and beauty depend greatly on its suffering in the early stages.

"That clay he's cutting up has been stored away there for a year - a hundred years would make. it better if we could let it wait," remarked the guide.

Along a dim and clayey corridor the guide now walked ahead. His great white apron, his iron-gray hair and mild face all seemed a part of the picture. He is a potter through and through. His is the spirit of creation. He turned a key in a door and swung it open. This is the chamber of secrets. It is here the master potter sits long hours, his mild countenance bent over a new experiment in glazes or body color or texture or a new tint from the kegs and boxes of bright mineral paint. There is an experimental sliproom in this room, where the whole process of preparing the clay is carried on in miniature exactly as it is done in the real sliproom. Here the colors are ground and boiled, and fused to obtain the clear, pure reds, yellows, whites and blacks, blues and greens that will come out the brighter from the firing.

"This is where the colors are made to mix in the clay.There's one color we've got to be careful about. Cobalt is a powerful color. A dust of it that you would hardly see will spread on a white dish into a great blue spot and spoil it. All white pottery has to be blued, though, and it's a delicate business to get the shade right. If it isn't blued it has an ivory tint.

"And now," continued he, showing a bit of what looked like opal, "here's a kind of borax composition that we use in our glaze. It's ground up and mixed in our special formula."

And so the clay is ready to take shape - the period of tribulation and distress is passed, and it leaves the cellar and soars above to be shaped in form of beauty to grace the habitation of man.

"Clay is different from anything else - there's always the uncertainty of what it's going to do. You've got to humor it and nurse it, it cracks so easily," said the guide as he led the way to the long room where the potters were hard at work forming the clay into utensils. A long series of benches against a row of windows, and bending over them a line of men, covered and spattered with the white slips from the necks of their long aprons to their heels. Sleeves rolled up and heads bent low, those potters were absorbed in their tasks, in the satisfaction of shaping and making things. A dozen, different trades are represented there. "We are at a great disadvantage," said the superintendent, "because each man has his own special kind of work to do, and knows nothing about any other kind. If a man is under the weather or lays off for any reason, we're handicapped; we can't call in somebody from another department, as they can in most places. The chances of waste are too big. Sometimes I've had to jump on a train myself and start off to another town where I knew there were potters working and try. to beg help in an emergency."

Of course, the first of all steps in making dishes is the making of the molds. The man who bent above his bench in his own little corner, turning out models, is an artist and a scientist in his own line. This work brings $22 to $30 a week. He makes the clay model of the vessel, and has to calculate it to allow for shrinkage in firing. A cup of ordinary size will shrink a tenth of an inch. He has to make the proportions pleasing and practical. Then the moldmaker takes it in hand, and here is another expert. These molds are made from the model in plaster of Paris, as many as will be required. There are molds whose outside surface shapes the vessel and those whose inside surface is the molding shape.

Meantime, the men have brought up the clay from the cellar and the henchmen are supplied with it. A youth takes a lump of the clay of the size his eye tells him will be just right for the purpose. He lays it on a wet plaster board, raises his bat (a plaster instrument like a huge round smoothing iron) and brings it down on the lump, with a force just sufficient to flatten the piece to the thickness needed and to leave it of the same thickness all over. "If he didn't do it just right," said the guide, "he'd break the bat." This man is called a batter-out, another potters' term. The

flattened piece, now looking very like a rolled-out slab of pastry, is taken

quickly and, with a peculiar twist and some force, it is laid upon the mold

of plaster. He is making a flat, oval dish with curving indentations about sides.

And as the wet slab of clay takes the contour of the mold, it appears like a

dish upside down. The molder is, meantime, working it and smooth with a small

bit of rub and a wet sponge - the only tools of the potter.

The

flattened piece, now looking very like a rolled-out slab of pastry, is taken

quickly and, with a peculiar twist and some force, it is laid upon the mold

of plaster. He is making a flat, oval dish with curving indentations about sides.

And as the wet slab of clay takes the contour of the mold, it appears like a

dish upside down. The molder is, meantime, working it and smooth with a small

bit of rub and a wet sponge - the only tools of the potter.

Deftly he whirls the mold around, stripping off the superfluous clay from the edge, and throwing it upon the the heap of clippings to be taken back to the mill. Rapidly then his helper lifts the mold with the wet dish upon it and carries it into one of the open compartments that, lined with shelves, fill up the central portion of the large room These compartments are warmed to dry out the clay in a couple of hours. Then a boy brings the mold out, loosens up and carefully removes the dried dish, and sets it upon a board to be taken down to the green-room, as the storeroom for green ware is called - and green here means unbaked.

Often a man is paid by the number of finished and unbaked pieces he delivers to the green-room - and he pays his helpers, or apprentices himself, thus running a miniature pottery within the works. This is specially the case with the jiggerman - the most delicate phase of the potter's work.

The jiggerman runs a kind of machine that is operated by the foot, but takes a steady hand, a trained eye and endless experience to manipulate it. His batter-out gets the clay ready, another helper stands ready to chum in the piece. This he does by taking a canvas bag, not unlike a large stocking, slipping it over what looks like an inverted bowl of extra deep dimensions; and then over the stocking he lays the clay, pressing it down to the mold. Then with a deft movement he lifts stocking and clay together, and places it within the mold on the jigger, draws out the canvas and leaves a complete sack-like lining of clay within the mold. The mold represents the two halves of a hallboy's jug, the two halves strapped firmly together. Your jiggerman has carefully thumbed down a bit of the clay to form the lip of the jug, and now he proceeds to apply his jigger, that presses the clay firmly against the inside of the mold, to the exact thickness required for the jug. With a whisk of his fingers he has the mold out of the machine, and a helper, a mold-runner, trots it into the warm room, while another is busy taking jugs from molds and returning the molds to the boy to strap together for the next jug. The jumbo jigger, that makes toilet jugs and other big vessels, is even more delicate to manage.

A

special man makes cups, another saucers, a sticker-up puts handles on cups and

covered dishes. Each is a special trade and each tradesman is an expert in his

line. A man can turn out as many as 2,000 dozen saucers in a week. But 1,800

dozen pieces a week of general shapes is a good record. In the case of oval

dishes that have irregular jogs and turns to their outlines, still another class

of workmen is needed. For these dishes, and the cover dishes, that are used

for vegetables and puddings all have to be made by hand, pressed together and

the mold trimmed down. It is all a man can do to turn out four dozen of these

a day. The man who makes bakers can turn out six dozen in an hour.

A

special man makes cups, another saucers, a sticker-up puts handles on cups and

covered dishes. Each is a special trade and each tradesman is an expert in his

line. A man can turn out as many as 2,000 dozen saucers in a week. But 1,800

dozen pieces a week of general shapes is a good record. In the case of oval

dishes that have irregular jogs and turns to their outlines, still another class

of workmen is needed. For these dishes, and the cover dishes, that are used

for vegetables and puddings all have to be made by hand, pressed together and

the mold trimmed down. It is all a man can do to turn out four dozen of these

a day. The man who makes bakers can turn out six dozen in an hour.

Then then are those gravy boats with a foot around the bottoms. These are actually made in pieces, which are stuck together. The mold is in halves , and the bottom is separate. Each half is lined with clay, and carefully molded in place, the two are fastened together, the bottom put in place, and the ridges along the edges trimmed off and smoothed down. This is done by the presser. This boy is able to make $2 a day, although he is just a beginner.

Another queer process they have is in the snaking of spouts for teapots. It would be next to impossible to mold piece so small and irregular, so your clever potter devised the plan of casting it exactly as metal spouts are cast. Some of the slip from the sliphouse is taken and a mold is filled with it in the shape of the spout. Then, when it has had time, say twenty minutes, to settle a bit, and adhere to the mold, the inside is poured out, leaving a hollow spout. This is placed on the teapot.

"The molds are made of plaster," said the guide, "because it's the most absorbent substance we can get. It takes the water from the piece quickest."

From the drying shelves the pieces go to be smoothed. A girl was occupied on this in one case, boys in others. She placed the dish on a wheel and smoothed down the edges, then with a wet sponge washed the surface, thus wetting the clay and leaving it perfectly smooth.

So the pieces have been dried out and taken to the green-room to await their turn at the biscuit kiln. The dried and unbaked vessels must be handled with utmost care, for they are very delicate. The potter has a way of his own of carrying a load of them on a board on his head, so balanced that he walks easily.

One of the great kilns was just being placed. It looked like a huge round room, of fire brick, with a smoky arched door and steps leading up to it. Up this step went the placers, some carrying laden saggers, some boards of larger vessels. The saggers are of fireclay made of a shape to accommodate cups, saucers, plates, dishes or whatever they are to hold. Plates, placed in tiers of fours with fireclay pins stuck into the sides, to keep them apart, require saggers resembling a four-leaf clover. These fireproof boxes are placed one upon another in rows within the kiln, until the whole space from roof to roof is filled, then the door is sealed up, and the fire is started.

The master potter leaned against the side of the roaring furnace, basking in its warmth, gloating in the process that was going on within.. "I've been a potter all my life," he mused, " I couldn't give it up. I wouldn't do anything else for three times the salary.

Potters are mostly poor, too, for there's an enormous loss connected with it. We count on four per cent loss in the biscuit kiln alone. Think of it - one of those plates over there for example - all the hands it passes through, and how easily it's broken. It may go through the whole thing and then have the boy smash it in taking it out of the kiln after it's baked."

He then opened a tiny door, as big as the palm of his hand, in the side of the furnace - a little double-closed door, lined with asbestos. "Look in there," he directed. And gazing into the white heat that shone within, one could discern a line of small white cones standing upright, in an alley left clear of saggers.

"Those are Sager cones," he explained, "No - nothing whatever to do with s-a-g-g-e-r-but the name of the German who invented them. They're made of a certain composition of clay and whiting and other substances, to fuse at a certain definite point of heat. So, when the furnace has reached a certain point, over topples the cone, and the furnace man, looking through the hole, knows what heat he's got. When the next stage is reached, another cone topples over, and so on. It takes 24 hours to bake a kiln of china."

When the kiln is drawn the china from it is called bisque ware, or biscuit, as the potter invariably has it. In the biscuit storehouse it is brushed by girls, with big brushes, taking off all the dust and roughness and removing any marks of the pins that may have marred the surface.

From this storehouse, the china is divided into two separate lots - one for the underglaze ware, the other for plain ware, or overglaze decoration. The decoration of china is one of the most interesting processes in the place, for it combines modern mechanical devices of the most mechanical kind with real work, and often calls the result "hand decoration." The Deldare ware is especially a Buffalo product, and a unique and beautiful one, too. It has a most unusual olive green body-that is, the olive green is mixed right in the texture of the ware. All over this, are the quaint designs from old English stories and ballads, done in arts and crafts style, in pure bright colors.

The printing press is the first instrument in the decoration of this ware. An engraved roll bears the patterns for cups, saucers, plaques and what not, just in black outlines. These are the output of a special designer and engraver employed in the pottery. Long sheets of semitransparent thin paper are run through the roll and come out bearing the patterns in a heavy oily ink. And a bevy of skillful-fingered girls receive the sheets. One girl cuts them up into separate patterns, and sticks them to the unglazed cups, saucers and other pieces at so much a pattern. A second girl rubs the paper tight to the surface with a padded stick. The pieces are then dried, and other girls wash off the paper, leaving the pattern stamped or transferred on the surface.

"How much do these girls make?" was asked. For they seem neat and bright and happy.

"It's mostly piecework," the master potter replied. "They make from $6 a week to $10 - of course the beginners make least and the best girls make most."

In another part of this department girls sat at long tables, bent closely over their paints and brushes, each with a finished piece of pottery before her, plying the color to the stamped piece in patches to correspond. Here all the underglaze decoration is done. The whole art of underglaze ware lies in discovering colors that will yield the right effects when the glaze is baked over them.

In the overglaze decoration, the same process of transfer work is employed, but over the glazed piece. Girls cover the glazy surface with a kind of size that sticks to the transfer paper. It takes a nimble fingered person to adjust the patterns delicately, to have the border around the edge match and keep even, to have the round pattern straight in the bottom and so on. One sometimes sees a pattern on a piece of china that looks as though the design had suddenly taken a start, and broken off short.

But now to the glazing vat. From the biscuit-ware room and the underglaze decorating-room, the pieces are taken to the dipping house, where a master of his art stands at a vat of glaze, seizes a plate or other piece in a kind of claw and quickly dips it, giving his hand a peculiar twist that assures the even distribution of the coating over the whole surface. A couple of girls hand him the pieces and take the dipped ones from his hands. The decoration is now covered by the creamy opaque coating.

In the second firing the glaze is fixed and changes from a white opaque to a transparent, glossy finish. It takes 2,400 degrees of heat to bake the pottery in the first process, and 2,100 for the glaze. The potter calls this the "glost" furnace.

The

overglaze decoration has to be fired - just as the amateur hand painter of china

fires his wares. The flame must be kept from the surface in this oven, so they

use what is known as a muffled furnace, as the baker does for his bread; 1,300

degrees suffice to set the paint. Last of all, the china is brushed and all

the bits of fireclay from the pins are scraped away and the pieces are piled

in separate groups. This is done by girls. Finally, the expert goes over them,

sorts out the best for firsts, the next for seconds, and the least perfect for

thirds.

The

overglaze decoration has to be fired - just as the amateur hand painter of china

fires his wares. The flame must be kept from the surface in this oven, so they

use what is known as a muffled furnace, as the baker does for his bread; 1,300

degrees suffice to set the paint. Last of all, the china is brushed and all

the bits of fireclay from the pins are scraped away and the pieces are piled

in separate groups. This is done by girls. Finally, the expert goes over them,

sorts out the best for firsts, the next for seconds, and the least perfect for

thirds.

"Yes, there's a fascination about it," the master potter repeated. "I've sat up most of the night waiting to see how an experiment would turn out. I've worked in the laboratory over some new mixture of clay or some body color, and I could hardly keep from tearing the furnace open to see what was going on. And then when the time was up I've broken open the sagger to get at my experiment - most always they're failures, and you find it all crumbled or twisted or the color spoiled, but - well, it's somehow a satisfaction, and you always want to go right at it and try again."

In Germany the potters' wages average 25 cents a day-in America $2.

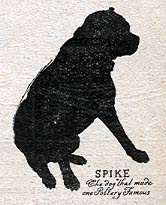

Spike, the Potter's Dog

The guide stepped to a door marked superintendent, and opening it gently, said,

"Spike," and out there bounded a fat brown dog. "It wouldn't

be right to let a visitor go without an introduction to Spike." said he,

patting the fat brown dog, "It wouldn't be right to let a visitor go without

an introduction to Spike," said he, patting the animal's head," Spike's

the potters’ dog - every potter in the country who comes to Buffalo has

to see Spike. He's part of the works." And Spike had retired again, with

the best of manners to the window, where he sat upon a table, gazing pensively

out into the yard. Spike knows everybody in the pottery and every process of

the work. He'll find his way among lanes of the daintiest china, galloping after

his master, and not so much as touching a piece in passing.

There

was a nest of robins just outside the window over the potters' lake, which the

two heads of the pottery were greatly interested in - so much so that they had

provided, a box for the birds to build in. With deepest interest they watched

the sprawling, hairless creatures develop to things of beauty; and Spike, sitting

at somebody's side, would seem to take it all in too. Then came the time for

the young to try their wings. Three of the four made it successfully and fluttered

their way to a neighboring tree. But the fourth was not so lucky. He, poor birdling

fell short of the mark and, in a minute later was wallowing in Potters' Lake.

There

was a nest of robins just outside the window over the potters' lake, which the

two heads of the pottery were greatly interested in - so much so that they had

provided, a box for the birds to build in. With deepest interest they watched

the sprawling, hairless creatures develop to things of beauty; and Spike, sitting

at somebody's side, would seem to take it all in too. Then came the time for

the young to try their wings. Three of the four made it successfully and fluttered

their way to a neighboring tree. But the fourth was not so lucky. He, poor birdling

fell short of the mark and, in a minute later was wallowing in Potters' Lake.

Nobody had seen the mishap - no human being - and so when Spike set up a vociferous cry, and pranced back and forth demanding quick exit, his master was somewhat surprised; for Spike is most dignified and orderly in conduct. But, to humor him, the door was opened and out went Spike like a rocket. A minute later he had plunged into the Potters' Lake and darting at a fluttering object in the water, had it in his mouth and was headed for the door again. Gently he laid his burden upon the ground and watched it shake itself - it was the fourth robin.

The old birds came down and whether they thanked their benefactor or not, only Spike knows, and he doesn't talk. The robin was soon winging as merrily as his brothers. And Spike sat again demurely at his window.